-

Studios

-

Support

-

Contact us

-

Products

Studios

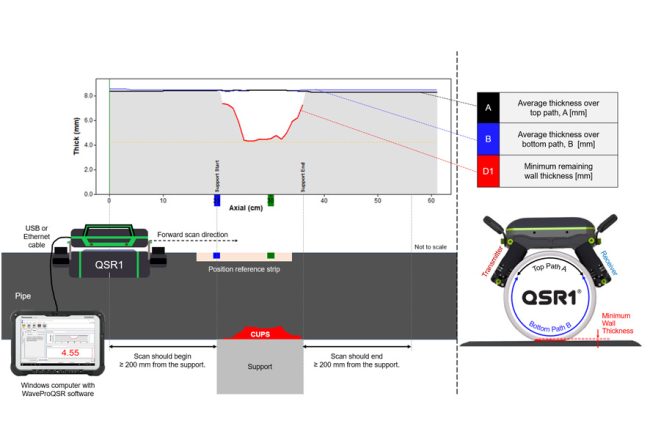

QSR1® is a simple-to-use scanner dedicated to quantitatively measuring the remaining wall thickness of the corrosion under pipe supports. It is lightweight, low-power, battery-operated, and highly portable. The device is positioned on top of the pipe and automatically scans the pipeline along its axis.

QSR1® uses EMAT technology to generate and receive short-range guided waves in a non-contact fashion to facilitate scanning, which is easy, repeatable, and relatively surface tolerant.

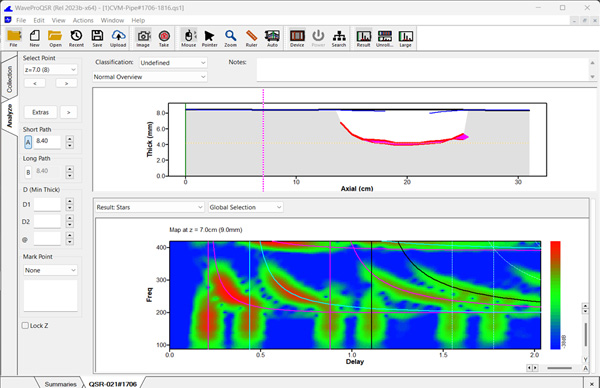

At each of the scanned axial position, the QSR1® transmitter sensor generates shear horizontal (SH) guided waves, which propagates in the pipe circumferential direction, and is received by the receiver sensor. The three main measurement results include the average wall thicknesses in the top and bottom paths, and the minimum remaining wall thicknesses, denoted by A, B and D1 respectively. The QSR1® data collection and scan configurations, including the total axial scan length, is controlled using the WaveProQSRTM software installed on a Windows computer.

The reliability of our equipment is the product of decades of experience in deploying thousands of advanced guided wave systems in the field.

Our QSR sizing accuracy has been proven by our customers in large oil and gas corporations, as well as third-party technology assessment by joint-industry projects around the world.

Our patented frequency-based signal processing method delivers true corrosion sizing accuracy.