-

Studios

-

Support

-

Contact us

-

Products

Studios

Our monitoring system has a successful track record of more than 15 years in the oil and gas industry. Its robust design withstands the harsh environments ranging from those found in polar regions to those in desert areas, onshore and offshore, above-ground and buried.

The system hardware, the gPIMS® line of products, consists of a sensor, which is permanently installed on the pipe, and an instrument, which collects and stores the data.

The sensors are common to all system configurations, whereas the associated instrument depend on the chosen monitoring strategy:

Find out more about scheduled and automated monitoring here.

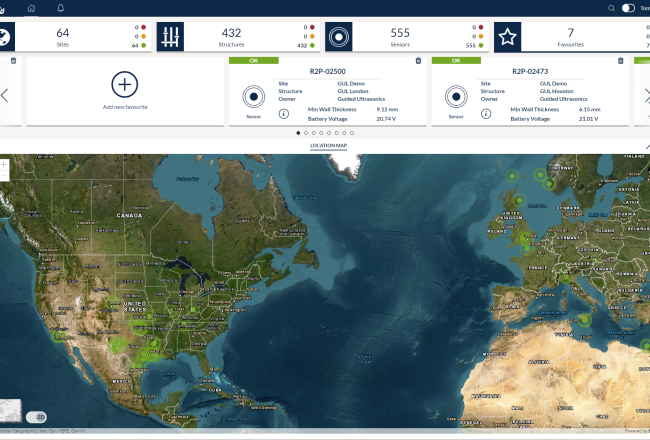

The complete range of capabilities for these systems is accessed via our cloud-based data management, analytics and visualization software, Monitoring Studio.

In automated monitoring, data is collected frequently by an autonomous, battery operated field control unit, which is permanently installed and connected to the sensor. This type of system offers many benefits over and in addition to scheduled monitoring systems:

The automated monitoring system is designed to take advantage of the data management, analytics and visualization power of the Monitoring Studio, which is accessed via a browser on your computer.

Our data integration service ensures there is an uninterrupted data flow from the moment data is collected to the point the information is displayed on your screen.

Check out our handy tool to configure your system.

The gPIMS® system hardware for scheduled monitoring incorporates a sensor, a connection box and a Wavemaker® collector instrument. The weatherproof connection box is typically mounted in an accessible location for connecting to the Wavemaker®.

As an intermediate solution between inspection and autonomous monitoring, the benefits of guided wave testing can be magnified with permanently installed sensors:

Check out our handy tool to configure your system hardware.

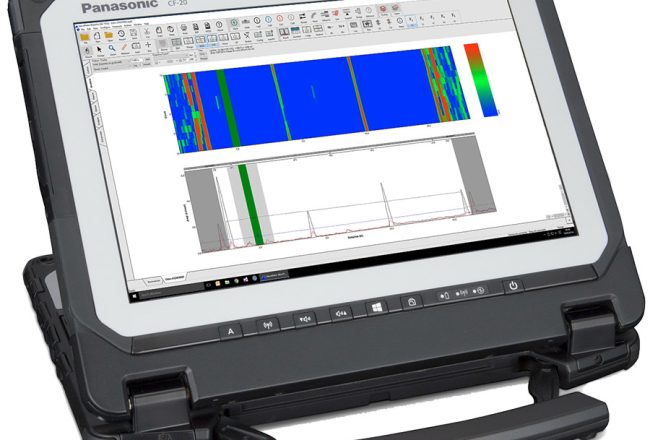

Scheduled monitoring involves a manual interaction and site visits, so data rarely happens to be collected more frequently than once every month. This is typically too low to take advantage of our advanced data analytics for Large Area Monitoring. Qualified service providers access tools within our WavePro software for data analysis, visualization and reporting.

All other capabilities, such as Small Area Monitoring, can be accessed via the Monitoring Studio software. The Monitoring Studio also acts as a data management platform for scheduled monitoring, making sure all your data is securely in one place and is never lost.

The hardware is designed so that it can be upgraded to an automated monitoring system should you want to take advantage of the data analytics at a later stage.

Our scheduled monitoring system hardware also allows also a cost-effective means of repeat inspection, where comparison of data is not the main objective and provision of repeated access for placing a screening sensor is difficult or costly: