-

Studios

-

Support

-

Contact us

-

Products

Studios

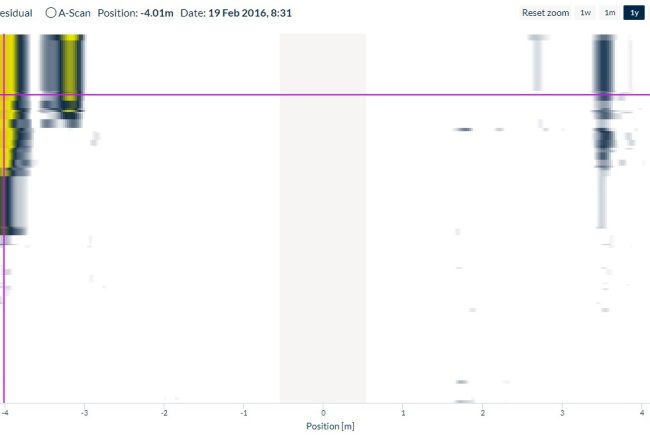

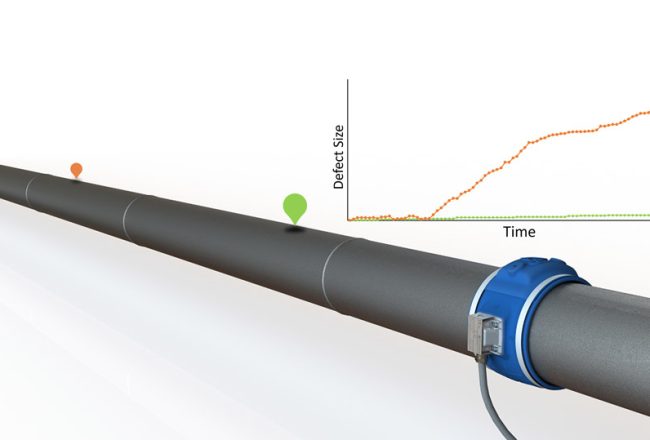

Our monitoring technology has enjoyed fast-paced development over recent years. Supported by robust hardware, proven to be reliable in some of the harshest environments on earth for almost two decades, we apply cutting-edge analytics to the data it delivers. The advanced signal processing and machine learning algorithms developed by our engineers take advantage of the frequent data delivered by the automated monitoring systems. They are designed to cancel environmental and operational effects on the results, providing superior sensitivity.

Using guided waves, our monitoring technology also delivers unparalleled pipe wall area coverage – the key to achieving high probability of detection and removing uncertainty in pipe condition. Our sensors are capable of:

Large Area Monitoring builds on the same technology, using the permanently installed gPIMS© sensor, with the added benefit of regular automated collections from the same measurement location. Data is automatically processed and presented to the user on the Monitoring Studio enabling:

Our Small Area Monitoring capability, using low frequency guided waves, covers the area underneath the sensor. The thickness measurements have a number of significant advantages over conventional point measurements:

Small Area Monitoring data are available to view in our unique Monitoring Studio service.